Power electronics involves a whole range of critical applications, from electrification to smart grids. It is a fundamental pillar for the entire industry to meet climate change demands and involves increasing energy efficiency, reducing our carbon footprint through new materials, and adopting new circuit topologies. Physical limitations prevent current silicon technology from achieving the higher power density, miniaturization, and energy conversion efficiency that the market needs from power products to meet growing environmental concerns.

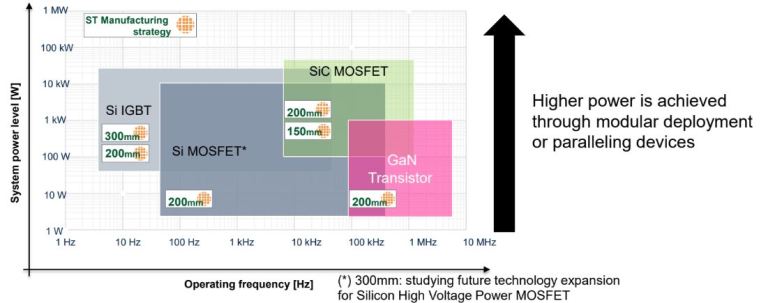

In 2018, the total worldwide electricity consumption was more than 22,000 terawatts per hour. The total global industrial segment alone consumed about 9000 terawatts per hour. If we can improve efficiency by 1% in the industrial market, the world would save total energy of 93.6 terawatts per hour and eliminate 32 million tonnes of CO2 emissions (Source: IEA (International Energy Agency)). In an interview with Power Electronics News during the APEC conference, Edoardo Merli, Power Transistor Macro-Division General Manager and Group Vice President of STMicroelectronics Automotive and Discrete Group, pointed out that Silicon Carbide (SiC) and Gallium Nitride (GaN) are two key technologies in meeting energy efficiency requirements. Wide Bandgap (WBG) SiC and GaN materials enable significant efficiency improvements in applications such as traction inverters for SiC and adapters/chargers for GaN. These two WBG semiconductors complement each other to address a wide variety of applications where energy efficiency is vital. However, silicon (Si) products are expected to co-exist with WBG products due to their cost-effectiveness in some low-power applications.

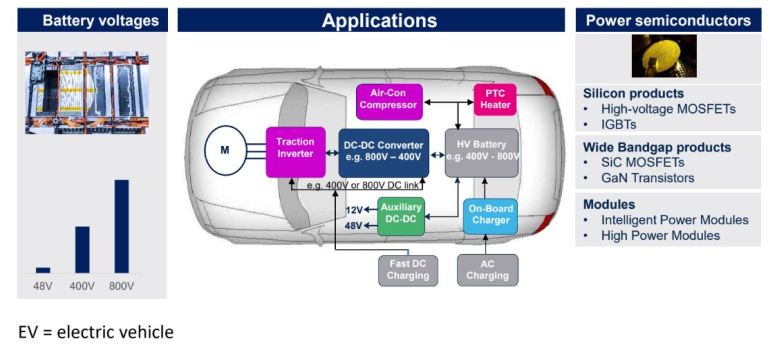

“The adoption of SiC in electric vehicles (EVs) is very important and it will be the same for other industrial applications. For example, in electric vehicles, we see a trend towards higher bus voltages, from 400 to 800 V. This has certainly started with luxury cars but will soon involve all the other vehicles to ensure high energy performance and therefore longer range while impacting cost, weight, and reliability, too. The 800-volt bus definitely guarantees even better efficiency,” said Merli.

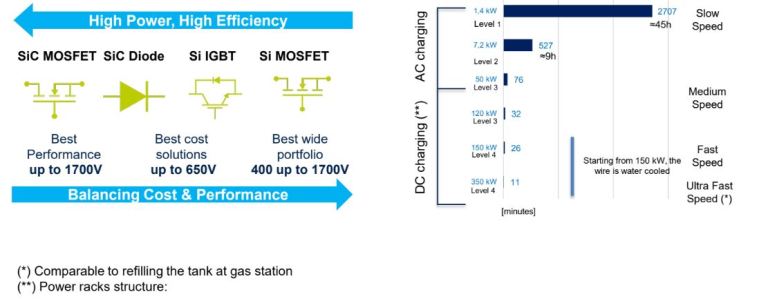

Another important factor is the reduction in recharging time for electric vehicles. This time is highly dependent on the heart of this technology, the battery, which is getting better and better in terms of energy density. “Here the 650 V and 1200 V SiC technology fits perfectly,” said Merli.

Figure 1: WBG materials enable new topologies; Totem-Pole Bridgeless Power Factor Correction can reach 99% of efficiency (Source: STMicroelectronics)

Figure 2: Silicon and wide bandgap power semiconductors (Source: STMicroelectronics)

Major trends in EV design are focused on battery voltage as Merli mentioned above, but also higher switching frequency (> 500 kHz) and bi-directional onboard charger topology. Moreover, high level of integration, better thermal management, and smaller magnetic components are also being addressed.

Charging Stations

The advent of e-mobility also drives the industry infrastructure of charging stations which is key to the adoption of electric vehicles. “Electric vehicles have zero emissions, and the industry is going in that direction. Renewable energy is playing an important role in that field, to have the whole industry highly support sustainability is critical. Solar energy, wind energy, they will make a strong contribution also linked to the general policies of international authorities. And the impact of Covid is pushing even more in that direction,” said Merli.

Silicon carbide will enable better efficiency so that all the powertrain in the industrial chain can be built efficiently. The next electric vehicles will be part of a complex smart grid and the key point, as Merli pointed out, is to have a complete bi-directional smart node. “A bi-directional grid is definitely the key to the future balancing of the energy grid, and the use of new wide bandgap materials will help us go down this road faster and faster,” said Merli.

The most common charging method uses an onboard charger that accepts AC voltage, i.e., the main power supply of a conventional household. Unlike AC chargers, the car battery can be directly powered without the onboard charger. DC chargers are bigger, faster, and represent an exciting breakthrough for EVs (Figure 3).

The further development and adoption of electric vehicles will undoubtedly require additional evolutions of the battery sector, which will be the engine of the next, present-day electric transport. Charging stations follow the technology trends of electric vehicles and their powertrain. In all this, the goal is to have gigafactories to produce batteries.

It is essential to support the entire supply chain, from the primary production of the materials to the secondary processes in which the minerals are recycled. Following European regulations, lithium will need to be recovered and recycled, and many companies are already organizing to meet this requirement. Future challenges will include mining and the costs associated with optimizing the production of these batteries.

“There are many models that are helping to optimise performance but also recycling, which can include a second life for the battery for even non-automotive applications. Reusing will have to involve new solid-state technologies and the use of different types of materials will make it even easier to recycle the battery at the material level,” said Merli.

Also an industry focus: The development of faster and more efficient charging-station technology requires good communication and continued efforts to deliver components that can economically handle a large amount of power used to charge electric vehicles. In other words, an increasingly intelligent charging station must go hand-in-hand with the evolution of electric vehicles. For semiconductors, there is a lot of interest in SiC and GaN technology. SiC-based power devices are driving a radical transformation of power electronics, thanks to a combination of excellent physical and electronic properties.

Substrate

The SiC substrate is undoubtedly one of the key elements in the technology and it is for several reasons related to processing efficiency. “From a production point of view, the silicon carbide substrate has a higher defect rate, and this requires greater attention to correcting the various errors. Another essential aspect is the availability of the substrate and a structure designed to guarantee volumes. About two years ago we acquired Norstel AB for these very reasons,” said Merli.

The acquisition of the entire Norstel business has strengthened ST’s entire internal ecosystem in SiC, increasing the company’s flexibility while allowing it to better control progress on yield and wafer quality to support its long-term roadmap and business. Norstel—now ST SiC AB—is currently producing 150mm silicon carbide blank and epitaxial wafers, as well as doing R&D on the production of 200 mm wafers, to ensure, as Merli pointed out, the volume and quality levels of substrates needed to produce MOSFETs and diodes in view of the massive adoption of the technology in the automotive and industrial markets in the coming years.

“Norstel/ST SiC is already working on the 200 mm technology to have a kind of fully integrated production of silicon carbide from the substrate to final product. Before acquiring Norstel, ST made the decision to develop our own fab for the substrate which will be integrated with the rest of the production so that by 2024, ST would have a fab covering >40% of our internal wafer consumption, with the rest coming from other commercial agreements, like those we’ve already announced,” said Merli.

The physical characteristics of SiC allow for an ideal physical structure for high-power electronics, improving the form factor in terms of weight and shape, which is critical for automotive. “The superior thermal behavior also allows assures better heat dissipation and therefore for significant savings in the cooling system. So, this is definitely a key advantage of silicon carbide versus IGBT or silicon solution. Many OEMs are employing SiC – we have a few announced relationships and even more unannounced ones. And now there is the shift towards a higher average voltage which again increases the gain of silicon carbide in terms of efficiency versus IGBTs. Still IGBTs will not disappear from power electronics, they will remain in the market for a long time,” said Merli.

“Silicon carbide can reach junction temperatures of over 300 °C (and over 200 °C when packaged) so we have to also look at the packaging material. There are studies ongoing for new materials, new topologies, and new techniques to exploit all the wide bandgap characteristics, and offer a package with reduced parasitic effects,” said Merli.

Energy Storage and Space

WBG power modules offer features and capabilities that are orders of magnitude greater than their silicon counterparts. They are also intrinsically radiation-hardened (rad-hard) and offer a theoretical junction temperature operation of up to 600 °C. This technology could provide power systems with power densities up to 10× higher than current silicon-based devices in addition to lower cooling requirements.

SiC promises lighter-weight components for lower energy consumption and lower emissions for the aerospace industry. This material facilitates higher switching frequencies and higher power density for a given voltage and current rating in a smaller, lighter device.

Just like silicon, GaN can be used to create semiconductor devices such as diodes and transistors. A power supply designer could choose a GaN transistor instead of silicon for its small form factor and high efficiency. GaN transistors also dissipate less power and offer higher thermal conductivity, compared to silicon devices with higher thermal management requirements. “For avionics, we see the wide gap material again offering a significant reduction in terms of volume weight and then, on the top of that,the possibility to save a lot in terms of cooling systems, which is very important for electric aircraft,” said Merli

Zero emissions are a target many nations are aiming to reach by 2050 and investments have been allocated by both the public and private sector to energy storage companies to help them reach this goal. Energy storage allows electricity to be saved and offered later, supporting the electricity grid and reducing greenhouse gas (GHG) emissions. Energy storage can complement renewable energy and distributed energy resources by offsetting the need for pollution-emitting power plants.

“From a reliability point of view GaN has reached a good level of stability and can definitely be used for energy storage, even if energy storage devices today are still being mostly addressed by silicon carbide. So, we are working with a number of companies providing them with silicon carbide solution for several parts of the smart grid.”

The future is definitely going greener, and power electronics will play a primary role because people, industries, and governments are recognizing the importance of the planet and of improving living conditions by reducing CO2 emissions. “It is essential to invest not only in technology but also in human resources with the professional profiles that will drive the development of new topologies by using new materials, because for us, developing the product means developing the technology. Simulation tools that allow us to model, for example, the electrical and thermal behaviours that will allow us to finalize the whole system,” said Merli.