One could reduce HVAC (Heating Ventilation Air Conditioning) energy consumption with more control. And one could get more control with a $3 microcontroller IC in physical devices that are networked together with reliable communication. Devices include:

- Motorized dampers inside ducts.

- Motorized dampers at vent openings.

- Fans inside ducts.

- Motorized valves at radiators.

- Pumps that moves 60°F water from ground source into radiators and heat exchangers

- Pumps that move water from thermal storage tank in basement into radiators and heat exchangers (e.g. water heated or cooled via solar when sun shining).

- Sensors (e.g. occupancy, indoor/outdoor temperature, sun, wind pressure).

With the above technology, one could:

- More precisely control airflow from central HVAC fan.

- Move air from one room to another room while HVAC is off (e.g. move cool air from basement to warm office on 2nd floor without turning on central HVAC).

- Route ground source 60°F water as needed.

- Route thermal storage water as needed.

- Integrate large appliances, thermal storage water, ground source 60°F water, and central HVAC.

Devices with processors exist, yet we are not doing the above due to:

- A standard way to electrically plug the above devices into a building does not exist

- A common operating system for all devices that supports plug-and-play and reliable integration does not exist.

- Standard physical plug-in modules with fans and dampers does not exist.

Researchers are working on the first two obstacles (i.e. standard electrical cable and operating system), as described in Using processors and software to make buildings smarter.

This article focuses on the last remaining obstacle, which are replaceable standardized plug-in fans and dampers. Standardization reduces cost via commoditization. Plug-and-play reduces cost via less design cost and less installation labor.

One would want a system whose additional cost is paid for with reduce energy bills within a reasonable period of time. If researchers can do this, then mass adoption becomes feasible.

The good news is development costs are low, and a decent amount has already been completed at Utah State under Professor Graham. Perhaps the hardest part is the operating system; however, this has already been coded and is available to others open source. This means anyone can copy and modify at no cost.

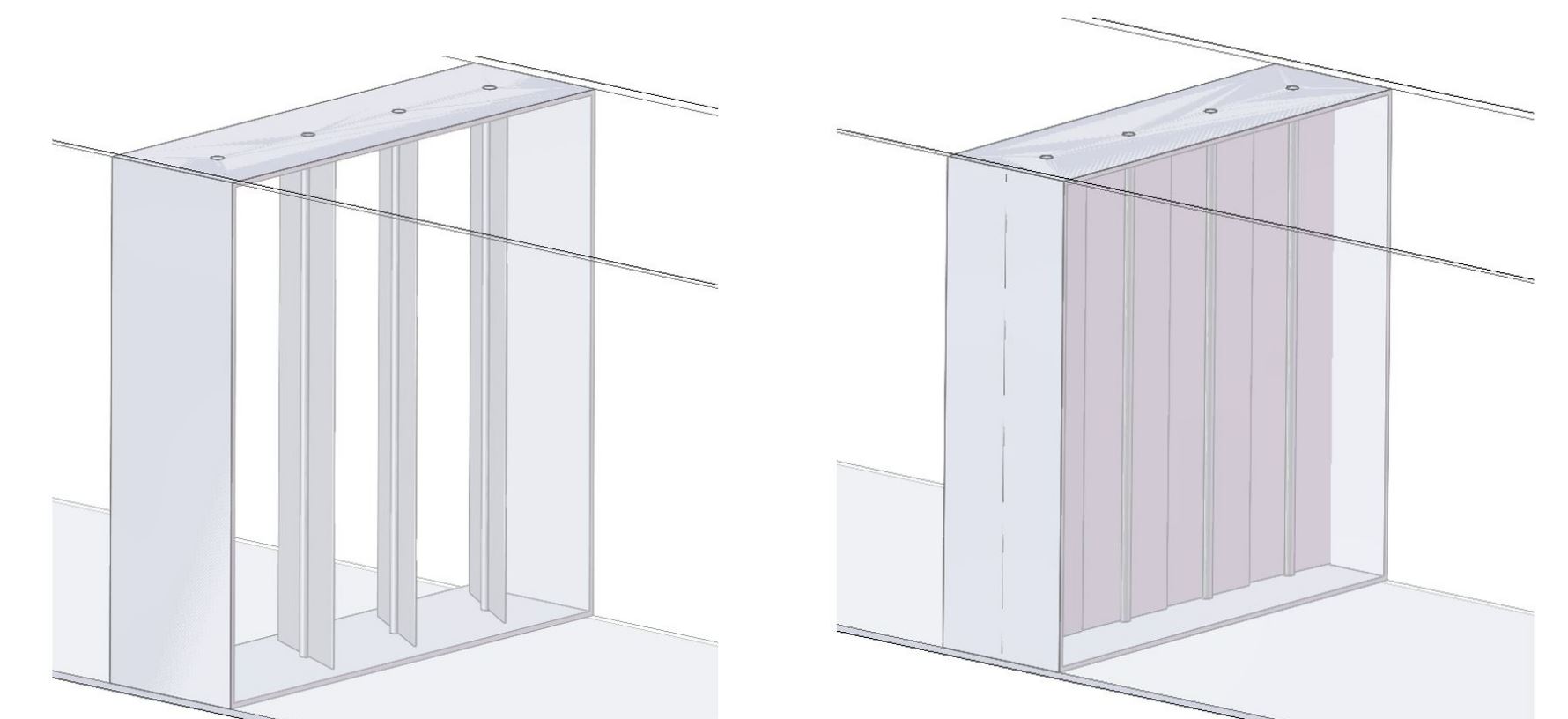

Standardized Plug-In Fans and Motorized Dampers

If one places a proprietary damper or fan in a duct and it fails every 15 years while the building lasts 100 years, and the manufacturer stops production after 5 years, then the building will degrade in value due to difficult to obtain replacement parts. The only way to resolve this is to make use of standardized plug-in modules at vent openings.

For example, to replace a fan or motorized damper within a duct, one would remove the vent cover, reach into the duct, remove ~4 bolts, unplug the module, remove through vent opening, and replace with new standardized module, plug-and-play. These would be manufactured by many companies, to ensure support over many years.

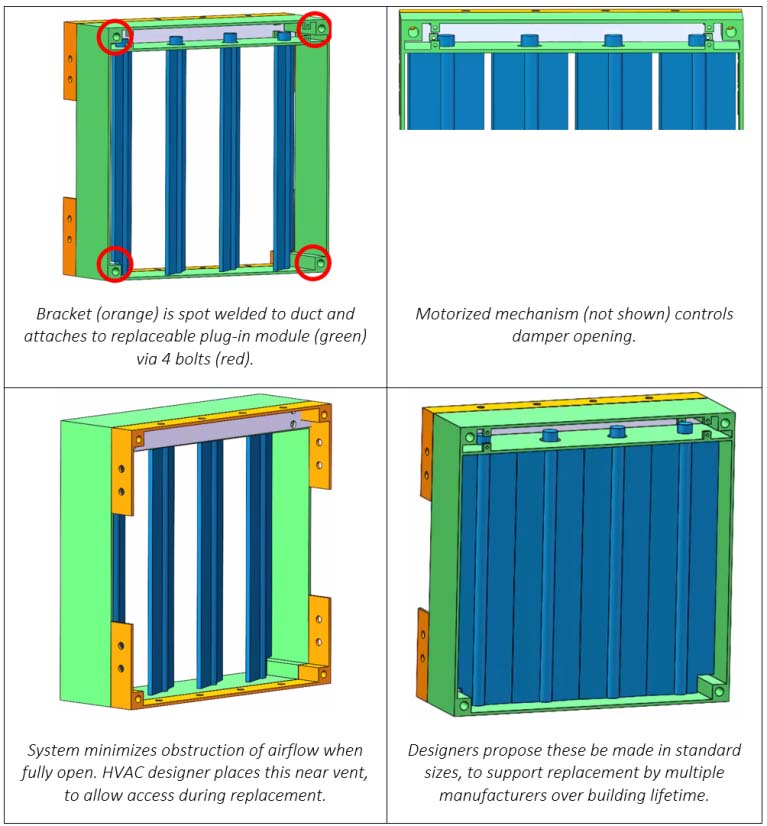

Motorized Damper Module

Shown in Figure 1 is an example of a proposed standard for motorized damper modules. Each module attaches to a bracket via 4 bolts, and the bracket is spot welded to the duct wall. One positions this near a vent opening to support replacement. These would be available in standard sizes which match standard ducts sizes; and standardization would allow one to replace with units from different manufacturers. One could place this in-line to control duct airflow; or place in the channel between duct and vent to control air into one room.

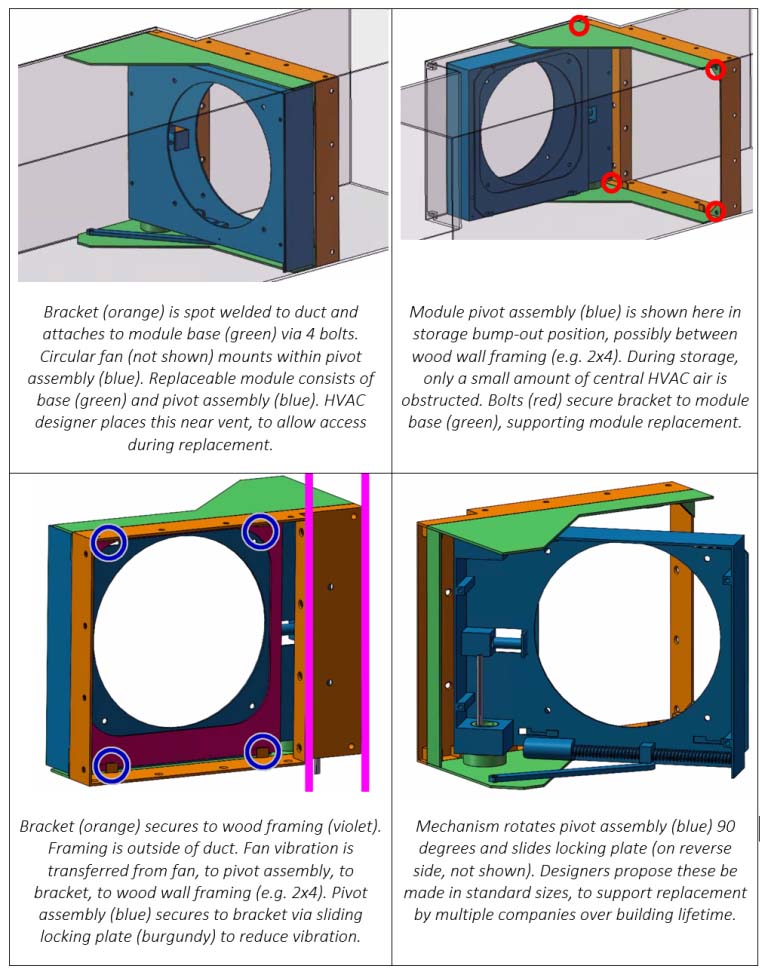

Pivot Fan in Duct Module

Shown in Figure 2 is a proposed standard for pivot fan modules. Each module either resides in a storage position while the central HVAC fan controls air; or deploys to an in-line position. If deployed, it could either act as a booster fan while the central HVAC fan is on; or it could move air between rooms while the central HVAC fan is off. A powerful fan might shake; therefore one would need to secure to a hefty bracket that attaches to wood framing (e.g. 2×4) in the wall. Like the above motorized damper, this would be available in standard sizes and it would support replacement near a vent opening.

Replaceable Fan Module

Below is a suggested mechanical standard for a replaceable fan module. This design is free and open, which means anyone can modify and use at no charge. For details, click here.

Replaceable Damper Module

Below is a suggested mechanical standard for a replaceable damper module. This design is free and open, which means anyone can modify and use at no charge. For details, click here.

Buildings Need Standards

A standardized system would support replacement by multiple manufacturers, with the hope of ensuring maintenance over a building’s lifetime. This requires manufactures to agree on the mechanical interface between bracket and plug-in module, for several module sizes (e.g. 2x10x10 in, 3x12x18 in). More specifically, the following parameters would need to be agreed upon at a standards body meeting: module height, module width, position of bolts, thread size, position of electrical connector, connector type, position of pivot, and thickness of module. Researchers have proposed values for several common module sizes; with the hope that industry engineers will later rework to their satisfaction.

The proposed fan/damper standard is similar to a proposed standard for thermal covers that automatically deploy over windows, as discussed in Standards Are Needed to Thermally Cover Windows.

Conclusion

With relatively little money, the world could develop standardized plug-and-play components that provide more control over air. To learn more about this development, click here.

Mr. Weinreb is the Director of The Manhattan 2 Project and has published over 25 articles on how to tackle climate change.