In the U.S., data center power consumption is expected to continue growing at a rate of 4% to 5% annually until 2022 and beyond.

With capital investments ranging from hundreds of millions to billions of dollars, it’s no surprise the owners of state-of-the art data centers are doing everything possible to drive down costs. And with the energy to operate data centers representing 3% or more of worldwide power consumption,1 maximizing efficiency is a priority. Combined, these two factors drive two trends: a move toward standards in design of data center equipment and a matching push for high efficiency. When looking at powering the compute equipment, these trends converge to drive the evolution of 48-V power supplies.

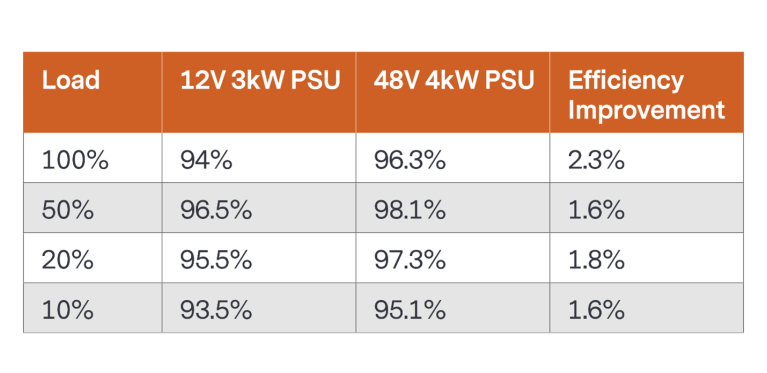

The route to standardization is exemplified by the Open Compute Project’s (OCP’s) Open Rack initiative, which rolled out ORv3 in 2019.2 In response to demands for increasing power density at both the component and system level, the latest 21-inch–width open-rack design supports 48-V power delivery schemes, which provides significant advantages compared with prevalent 12-V architectures. These advantages include improved power-conversion efficiency that leads to ~1.1% power bill reduction (as estimated by the U.S. Energy Information Administration), improved thermal performance, and ~1.5% lower hardware costs. The efficiency benefits of 48-V architectures will be discussed in greater length later in this article.

Part of the hardware cost reduction is the current industry shift from classic power supply modules to power shelf architectures. The rack-mountable configuration of a power shelf is space-efficient, taking 1U of a 44U rack for the supply and 1U for battery backup unit and thus allowing each rack to accommodate up to 42 compute blades. Importantly, the integration of lithium-ion battery backup units with other components on the rack confers major advantages in terms of granularity and the elimination of long cable runs to separate rooms housing lead-acid battery banks. The same advantages translate to organizations using 19-inch open-frame racks, which have compute density (and thus power requirements) that parallel those of organizations using OCP designs.

The drive to save energy

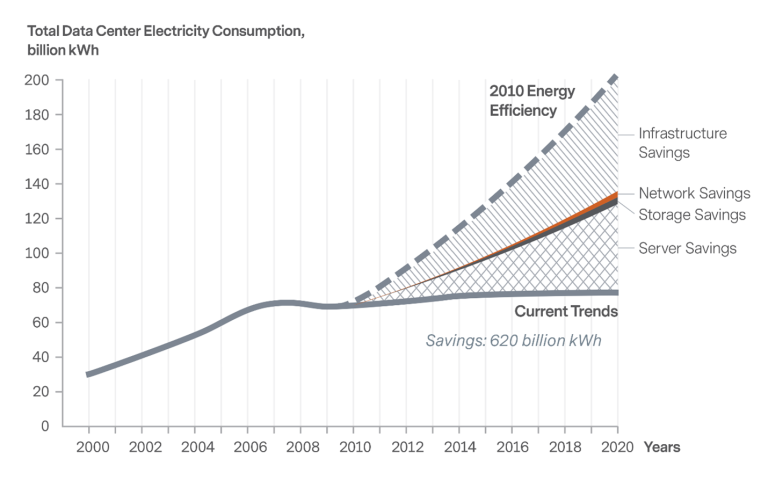

In the U.S., data center power consumption is expected to continue growing at a rate of 4% to 5% annually until 2022 and beyond. This is far below the rate of growth in data center compute capacity and is a testimonial to the effectiveness of industry efforts to reduce power footprints while improving the efficiency of power supplies. While improvements in efficiency since 2010 have had a dramatic impact on power usage (Figure 1), the need for continued innovation is clear.

Several trends in compute architecture are driving increased power demands in data centers in the next few years. AI and cloud applications are boosting the adoption of advanced hardware, including microprocessors, GPUs, FPGAs, and ASICs that require greater power levels. For example:

- Advanced processors, including Intel’s “Sky Lake” and AMD’s “Rome,” are projected to consume between 230 and 300 W, and Intel’s “Ice lake” is projected to consume about 450 W.

- Nvidia’s current and upcoming GPUs are expected to consume about 600 W.

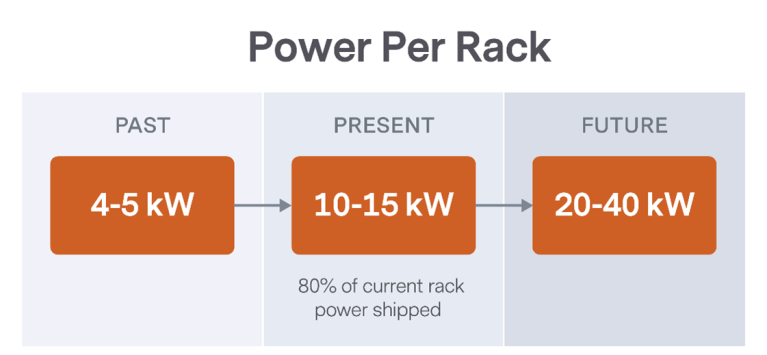

These equate to significant increases in required power per rack (Figure 2).

The increase in power requirements per rack to 20–40 kW is a principal reason for the move to 48-V power architecture. As output power increases, there is an increase in distribution losses as well as the size of output bus bars. With this in mind, the efficiency of 12-V architecture in comparison with 48 V must be considered.

Conversion efficiency is just one element of the equation in determining power use in a data center. Other factors favoring 48 V instead of 12 V are that current draw for the same power level is reduced by 4× and distribution losses are 16× lower. This equates to better thermal performance and therefore reduced cooling requirements, as well as the ability to reduce the size of power bus bars, all of which factor into overall power use to operate the data center.

What do these figures mean in terms of actual costs? Consider a data center with overall power use of 10 MW, with servers that consume 50% of that energy and a power usage effectiveness (PUE) of 1.6. A 2% increase in the efficiency of the server power supply leads to a 1.6% decrease in electricity use. That translates to 1.4 million kWh saved annually, which is equivalent to reducing CO2 emissions by more than 21 million pounds (Figure 4). At $0.07 per kilowatt-hour, that’s $98,000 in savings. In a data center with hundreds or thousands of servers, this kind of savings adds up fast.

Interoperability is key to standardization

Today, roughly 15% of data centers have adopted 48-V power architectures, with the remainder continuing to use 12-V power architectures. However, the transition is accelerating, and Advanced Energy estimates that as much as 50% of data centers will implement 48 V by the middle of this decade.

As noted earlier, a major economic driver for data centers is standardization to achieve equipment cost efficiency. When considering power supply designs, this requires commitment by suppliers to support interoperability by adopting non-proprietary control methods and ensuring that both voltage and current loop bandwidths can be appropriately matched in heterogenous environments. Advanced Energy is active in these standardization efforts as a key contributor to OCP ORv3, collaborating with major OCP users and leaders in the hyperscale data center segment to create a common power platform for customers across deployments, which ultimately leads to increased adoption and economies of scale of 48-V architectures.

Today, Advanced Energy offers a range of 48-V supply solutions, including a family of ORv3 power shelves featuring 97.5% efficiency and output levels of 18, 24, 30, and 34 kW, as well as lithium-ion cell BBUs in a 1U, 21-inch rack configuration. An EIA rack-frame power shelf with 97% efficient power supplies and 36-kW total power output is also available.

The future of data centers

Looking to the future of data centers, it is likely that as server power demand exceeds 30 kW, forced-air cooling will no longer be sufficient to maintain a safe operating temperature. The next steps are varied approaches to liquid cooling,3 which take advantage of the superior thermal transfer properties of liquids relative to air. Most typically today, this means direct-to-plate techniques, but on the horizon is immersion cooling, in which server components are submerged in a non-conductive fluid. Advanced Energy is already working on power supplies that readily adapt to liquid cooling, enabling it to be used in immersion-cooling platforms.

On the power distribution side, continued increase in overall demand will ultimately lead to DC schema. The likely transition is at 400 V, as direct current at that level eliminates requirements for a power-factor–correction stage and thus achieves up to 99% efficiency.

There’s no doubt that this greater efficiency will be required as data centers continue to grow in both individual size and the number of installations. Data centers and cloud services form the backbone of a digital lifestyle that is seeing the amounts of data generated worldwide grow exponentially. And with the adoption of IoT devices projected to contribute to an explosion of data, from 18.3 ZB in 2019 to 73.1 ZB in 20254 — an almost-fourfold increase — data centers will continue to play a critical role in the digital economy. Advanced Energy is a key contributor of this growth, powering the data center’s hardest challenges with highly efficient, high-performing power supply solutions.